Nabors’ SmartDRILL™ process automation has demonstrated value across the Nabors fleet by reducing connection times and decreasing lateral vibrations to mitigate unplanned trips. It has even delivered outsized impacts on non-Nabors rigs, by reducing connection times and improving connection consistency.

Now adding robots to the mix, Nabors is exploring the upside of pairing machine and process automation together on land drilling rigs.

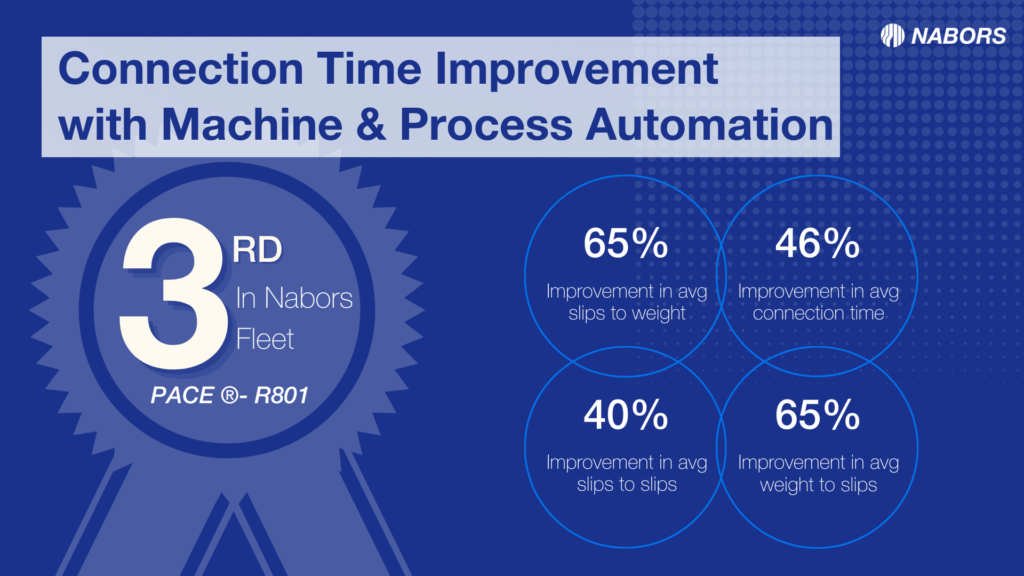

The first rig to run these technologies together – Nabors R801, which is working for ExxonMobil in the Permian – has improved on its own connection times by 46% and is now third across Nabors’ fleet for connection time performance. This was one of the best wells drilled with R801, so far.

The best part? The connection time is nearly the same, every time, and can be replicated across any rig without a full upgrade—just the installation of the Canrig robotic pipe handling equipment and Nabors SmartROS™ rig operating system.

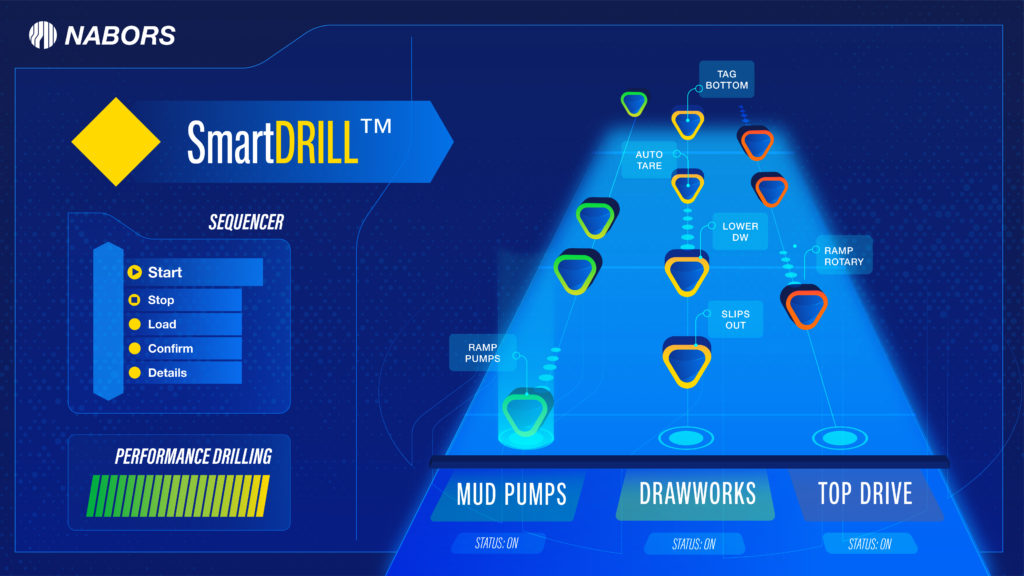

So how does this all work? In building R801, Nabors identified the need for a rig operating system with a machine layer and flexible sequencing engine. This requirement laid the foundation for the operating system that’s now installed across all of Nabors’ SmartRig fleet, and some third-party rigs—SmartROS™.

“Across the industry, we’ve been building automated solutions to achieve better, more consistent performance. By combining process automation solutions, like SmartDRILL™ and robotics, we’re one step closer to fully automated drilling processes to keep crews out of the red zone and consistently achieve top tier performance,” said Michael “Farley” Whatley, Senior Manager of Controls and Automation, who has been instrumental in the success of R801.

SmartDRILL™ is pre-programmed with drilling recipes that reflect best drilling practices across all major basins. The instructions communicate with critical rig components at the click of a button on the driller’s HMI.

Low capital intensity upgrades are what will elevate drilling performance without having to spend millions of dollars per rig. Upgrading the rig to include a control system, like SmartROS™, to enable process automation and robotic upgrades of some rig equipment will ensure contractors maintain capital discipline while mitigating performance variability.

“In 2021, solutions like our SmartDRILL™ process automation helped to reduce instances of variability in performance across our rigs,” said Blakley Farrow, Manager of Operations for SmartDRILL™. “We saw a lot of turnover in the oilfield and the deployment of process automation gave our customers confidence that they wouldn’t see the effect of some of these challenges in their drilling performance. That being said, the success of process automation is attributable to awesome drillers, trainers and 24/7 support from our remote operations center”.

Nabors is looking forward to seeing more performance improvements that are made possible by talented people, advanced technology and an unrelenting pursuit to be the driller of choice for customers.