Offshore Completions

Nabors offers conventional and proprietary tubular running services for running production tubulars with or without control lines.

Conventional Tubular Running Services

- Available on tension leg platforms, inland barges, jack-up rigs and floaters

- Components of a package include the following services to be performed:

- Hydraulic Pusher Arm System

- Non-Marking Corrosion Resistant Alloys (CRA)

- Weight Compensator

- Torque Turn Monitoring

Proprietary Tubular Running Services

- Available on tension leg platforms, jack-up rigs, floaters and drill ships

- Components of the package include the following services to be performed:

- MCLRS 6’ Scoping Unit

Or - A-Frame System (Automated) with conventional elevators hydraulic compensator & ECDS System

- Weight Compensator

- Automated Cart System

- Torque Turn Monitoring

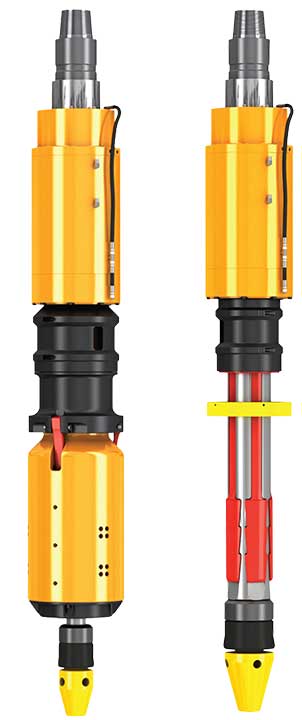

- MCLRS 6’ Scoping Unit

A-Frame System

Design and Features:

- Provides our customers with a single system to automatically manipulate the tong while having the ability to assist with placing the control line against the pipe

- One-lift system with a simple and efficient rig-up/rig-down process that takes less than an hour

- Accepts control lines from vertical or horizontal entry points

- Eliminates working from heights

- Can be used with a back-saver slip assembly or Flush Mount System with minimal modifications

- Can be used with landing string and umbilicals

- Designed for completion operations from a single zone to multi-zones

Control Line Pusher Arm

Design and Features:

- Compact version of the A-Frame System, consisting of the cart, slips and pusher arm

- Pushes the control lines to the pipe to secure control lines to pipe with clamps

- Available for use at a 45° or 90° angle from the well center

- Eliminates working from heights

Scoping MCLRS™

Design and Features:

- Eliminates control lines in the tong area from overhead sheaves and running through slips

- Simple and efficient rig-up/rig-down process that requires only three lifts and can be done in two and a half hours or less

- Standard components make the MCLRS unit portable and versatile enough to fit most rigs

- Guides can be positioned so that control line clamping can be performed from up to four sides 90° apart from each other

- Efficiency is optimized as the tongs are operated remotely on the top platform

- The unit’s small footprint maximizes rig floor space to increase efficiency of tubing running operations

Package Accessories

Automated Gravel Pack Cart System

- Used on both conventional and proprietary packages

- Allows personnel to move the tong forward, backward, up and down without hanging from a rig tugger line

- Hands-free application means less personnel in the well center space

- Eliminates pinch points

Gear Cart (Automated Tong Handler)

- Adaptable enough to fit any IR Track system or rig or tong system

- No rig tugger line required to hoist tongs up or down

- Decreases the risk of hand injury

- Can operate with the Remote System Belly Pack

- Eliminates the Telescoping Arm

- Utilizes dual activity rig building stands of tubulars

- Can be used on the Main Rotary

- Available sizes:

- 22” XHT 100K Tong with BU

- 14” DP 100K Tong with BU

- 8-⅝” DP 85K Tong with BU

- 5-½” UHT with integral backup

Remote System Belly Pack Electric/Hydraulic

- Reduces personnel around the Main Rotary, also reducing hand placement and pinch points

- Provides a built-in ESD switch

- Adaptable to all automated offshore systems (A-Frame, Gravel Pack Cart, Sliding Slip, etc.)

- Utilizes a key for powering on/off

- Employs secondary retention before allowing function of rotary slips

- Provides operator with better mobility around the rig floor for clear line of sight

Drill Smarter with Nabors

Tell us more about your needs by completing the form below and a Nabors representative will contact you soon.

"*" indicates required fields